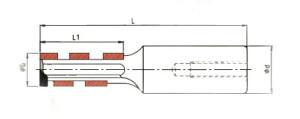

Straight shank cutter

The body of a cutter is made of special tool steel. The material of the blade is polycrystalline diamond, depending on the type of milling cutter. The special design of the body and the shape of the blade make it possible to achieve very high parameters of milling. As a standard, we make right-hand milling cutters, but, upon request of the customers, we can also make left-hand cutters.

| Numer | Średnica D | Głębokość skrawania L1 |

Długość całkowita L |

Głębokość x średnica mocowania d x L2 |

Z |

| P 2001225/1 | 12 | 25,4 | 70 | 12 x 35 | 1+1 |

| P 2001235/1 | 12 | 35 | 90 | 16 x 45 | 1+1 |

| P 2001625/1 | 16 | 25,4 | 85 | 16 x 45 | 1+1 |

| P 2001635/1 | 16 | 35 | 95 | 16 x 45 | 1+1 |

| P 2001645/1 | 16 | 45 | 100 | 16 x 45 | 1+1 |

| P 2001843/1 | 18 | 43 | 100 | 16 x 45 | 1+1 |

| P 2001835/20 | 18 | 35 | 105 | 25 x 55 | 1+1 |

| P 2001843/20 | 18 | 43 | 100 | 25 x 55 | 1+1 |

| P 2001835/2 | 18 | 35 | 105 | 25 x 55 | 1+1 |

| P 2001843/2 | 18 | 43 | 110 | 25 x 55 | 1+1 |

STRAIGHT SHANK CUTTER (NW) Z = 3, DIA 4mm

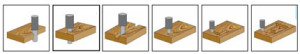

NW cutters are intended for CNC machines. They can work with the feed of 4–8 m/min., depending on the quality of the material to be milled and the diameter of the tool. The body of the tool is made of steel characterized by high bending and torsional strength.

Milled material: MDF, laminated or non-laminated particle board.

Expected number of sharpening operations: 10–12

| Numer | Średnica D | Głębokość

skrawania L1 |

Głębokość x średnica mocowania d x L2 |

Ilość płytek diamentowych |

| 1 | 16 | 27 | 20 x 50 | 5 + 1 HM |

| 2 | 12 | 32 | 20 x 50 | 6 + 1 HM |

| 3 | 16 | 37 | 20 x 50 | 7 + 1 HM |

| 4 | 16 | 27 | 20 x 55 | 5 + 1 HM |

| 5 | 16 | 32 | 20 x 55 | 6 + 1 HM |

| 6 | 18 | 37 | 20 x 55 | 7 + 1 HM |

| 7 | 18 | 27 | 20 x 50 | 5 + 1 HM |

| 8 | 18 | 32 | 20 x 50 | 6 + 1 HM |

| 9 | 18 | 37 | 20 x 50 | 7 + 1 HM |

| 10 | 18 | 42 | 20 x 50 | 8 + 1 HM |

| 11 | 18 | 27 | 20 x 55 | 5 + 1 HM |

| 12 | 18 | 32 | 20 x 55 | 6 + 1 HM |

| 13 | 18 | 27 | 20 x 55 | 7 + 1 HM |

| 14 | 18 | 42 | 20 x 55 | 8 + 1 HM |

STRAIGHT SHANK CUTTER (N1) Z = 3, DIA 2.5mm

N1 cutters are intended for CNC machines. They can work with the feed of 4–8 m/min., depending on the quality of the material to be milled and the diameter of the tool. The body of the tool is made of steel characterized by high bending and torsional strength.

Milled material: MDF, laminated or non-laminated particle board.

Expected number of sharpening operations: 4–6

| Numer | Średnica D | Głębokość skrawania L1 |

Głębokość x

średnica mocowania d x L2 |

Ilość płytek diamentowych |

| 1 | 16 | 27 | 20 x 50 | 5 + 1 HM |

| 2 | 12 | 32 | 20 x 50 | 6 + 1 HM |

| 3 | 16 | 37 | 20 x 50 | 7 + 1 HM |

| 4 | 16 | 27 | 20 x 55 | 5 + 1 HM |

| 5 | 16 | 32 | 20 x 55 | 6 + 1 HM |

| 6 | 16 | 37 | 20 x 55 | 7 + 1 HM |

| 7 | 18 | 27 | 20 x 50 | 5 + 1 HM |

| 8 | 18 | 32 | 20 x 50 | 6 + 1 HM |

| 9 | 18 | 37 | 20 x 50 | 7 + 1 HM |

| 10 | 18 | 42 | 20 x 50 | 8 + 1 HM |

| 11 | 18 | 27 | 20 x 55 | 5 + 1 HM |

| 12 | 18 | 32 | 20 x 55 | 6 + 1 HM |

| 13 | 18 | 37 | 20 x 55 | 7 + 1 HM |

| 14 | 18 | 42 | 20 x 55 | 8 + 1 HM |

STRAIGHT SHANK CUTTER NWZ Z = 2, DIA 4 mm

NWZ cutters are intended for CNC machines. They can work with the feed of 4 m/min. and higher, depending on the quality of the material to be milled and the diameter of the tool. The body of the tool is made of steel characterized by high bending and torsional strength.

Milled material: MDF, laminated or non-laminated particle board.

Expected number of sharpening operations: 8–10

| Numer | Średnica D | Głębokość

skrawania L1 |

Głębokość

x średnica mocowania d x L2 |

| 1 | 16 | 26 | 16 x 45 |

| 2 | 16 | 35 | 16 x 45 |

| 3 | 16 | 45 | 16 x 45 |